Figure 1. Material

and energy flows in foundries, according

to German Federal Environment Agency

(2004).

DUST EMISSIONS FROM FOUNDRIES IN TỐNG XÁ AND

INTEGRATION OF THE RESULTS INTO THE OBJECTIVES OF IWRM

K.

ASSMUS 1, V. KEUTER2, R. EMMERICH1

1University of

2Fraunhofer-Institute for Environmental, Safety and Energy

Technology (UMSICHT),

Abstract: This article presents results from dust measurement

programmes in foundries of Tống Xá, Việt

I. INTRODUCTION

According to the

study “Referenzdokument für Schmieden und Gießereien” of the German Federal

Environment Agency (Umweltbundesamt) in 2004 emissions to the air belong to the

major ecological hazards from foundries. Dust of different kinds and

compositions occurs in all major process steps. Dust concentrations produced

during melting of cast in an induction furnace reach up to 0.5 kg/t [7]. Apart

from typical compounds as SiO2 dust can contain metals and metal

oxides (Tab. 1).

Table 1. Typical compounds

of dust

from induction furnaces [7].

|

Compounds |

Dust ratio |

|

Fe total |

45.60 % |

|

SiO2 |

6.50 % |

|

MnO |

2.10 % |

|

Al2O3 |

0.35 % |

|

Ca |

0.1 % |

|

S |

0.1 % |

The

dust itself as well as the adhering emitted metals originating from the casting

and finishing stages can affect the human health. Anthropogenic sources of dust

within the foundry dominates over all combustion processes where dust is

emitted as flue ash or soot. This “anthropogenic dust'' consists of more than

80% of particulate matter below 10 µm. According to Lahmann et al. [9], the most harmful metals can

be found in particulate matter smaller than 2.5 µm, thus the respirable

fraction.

II. SITUATION IN TỐNG XÁ

Dust

on the outer side of workers’ respirator masks in Tống Xá foundries had

been already analyzed in 2001. These masks were not and still are not part of

workers equipment but had been distributed as part of this trial. High dust

loads and various ferrous flue ashes had been analyzed [10]. Because of this

and further studies, foundries had been focused to be a source of high heavy

metals contamination in the soil close to the industrial area.

Within

the foundries of Tống Xá predominant components for construction vehicles

and machineries as well as mining and cement industry equipment are produced.

Products from the fabrication process including e.g. molding, casting and

finishing are solely hand-made.

The data and following conclusions were part of interviews and plant

surveys by Emmerich [4] and Keuter [8].

Table 2. Process steps in Tống

Xá foundries

|

Process step |

Foundries in Tống Xá |

|

Molding shop |

Lost forms |

|

|

Clay based molding sands, chemical based

molding sands (sodium silicate process) |

|

Casting |

Melting of conditioned steel scrap |

|

Founding |

Casting in lost forms |

|

Annealing |

Annealing of unfinished castings |

|

Finishing |

Cast iron conditioning |

Primary resource for the melting process is mainly steel scrap of which

up to 200 tons per month and company is being processed. Within most of the

companies lost casting is applied with quartz sand as the raw material. Clay

serves as a binder; isolated water glass is used additionally. The mixing ratio

of sand to clay is 0.7:0.3 - 0.75:0.25. Some forms are brought into a fire

chamber for baking then dried and partially coated with a lead suspension.

Melting of the steel scrap is realized in induction furnaces in open top

pans. Additives are manganese, silicon (6 kg per cast) and aluminium.

Additional also paper, foil, paint, oils and grease can reach the cast by adherence

to the steel scrap. A large part of the cast products is being annealed for

adjustment of the microstructure. At the end of the production process

finishing of the products including removal of form sand, cast residues and

ridges or correct defects as well as partially applying protective coatings is

being performed.

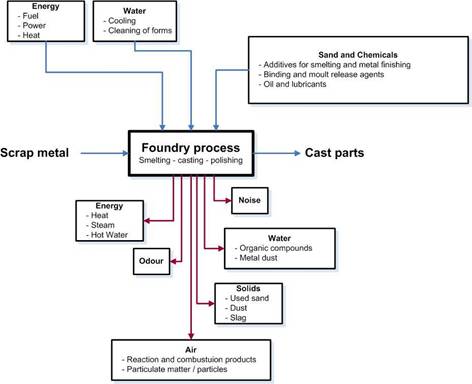

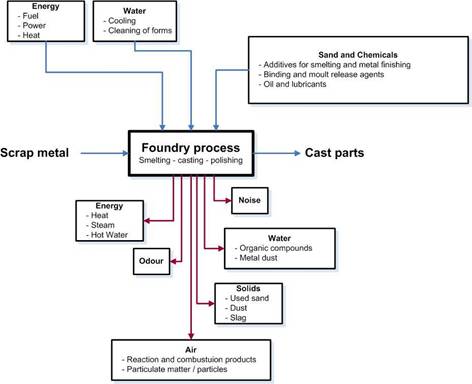

The following figure represents a simplified overview on the major

material flows in foundry processes. Input sources can be arranged in scrap

metal, energy, additives and water, output in cast products, energy,

wastewater, noise, solids, air and odour (Fig. 1).

Figure 1. Material

and energy flows in foundries, according

to German Federal Environment Agency

(2004).

III. INVESTIGATIONS

For verification of the previous studies and more detailed correlation

of specific data to the topics of the Integrated Water Resource Management

(IWRM) project, air samples had been taken in various foundries in Tống

Xá in summer 2008. The samples had been taken at different process steps within

the foundries, analyzed for particle sizes of the dust, particle counts and

elementary analysis.

In accordance with EN 481 several measurements which lasted each several

hours were made within the enterprises for determination of the particle

distribution and measurements according to occupational medicine requirements

of 2 x 5 min.

To determine the particle number and size in different production

sectors of the foundries a portable aerosol spectrometer (Grimm Aerosol Technik

GmbH, Model 1108) has been used. In total, more than 50 measurements had been

executed in seven foundries at different process steps. At the same time,

particle samples has been taken via air suction of the measuring device and

stored on a PTFE filter for further analysis. Measuring time and collected air

volumes differed according to the adjusted mode of measuring. The dust samples

had been analyzed using a scanning electron microscope (SEM) and a transmission

electron microscope (TEM). Hence it has been possible to determine the

elemental composition of the particles using energy dispersive X-ray analysis

(EDX) in combination with morphological studies.

Figure 2. Dust monitoring at casting process - measuring

program in one of the surveyed foundries in Tống Xá.

IV. RESULTS

Figure 3 gives an

overview of analyzed dust concentrations (particulate matter) in seven

foundries of the industrial area in Tống Xá. All measured concentrations

are above the limit thresholds of the German TA-Luft and even almost all above

the Vietnamese TCVN5937-2005.

Figure 3. Particulate

matter at different production stages of investigated foundries

in Tống Xá.

Figure 4. Percentage distribution

of chemical substances in four different production stages (one particle might

consist of various elements)

In Figure 4 results of elementary analysis show significant differences

in chemical composition depending on the location of sampling.

The incidence of elements can be described in descending order as

follows:

Molding:

Si>Fe>Cl>K>Zn>Ca>S>Na>Al>Mn

Finishing:

Si>Fe>Zn>Ca>Al>K>Cl>V>S>Mn

Molding + casting:

Fe>Si>Ca>Cl>Al>K>Mn>S>Mg>Cr

Casting:

Si>Ca>K>Al>Cl>Fe>S

The analysis has been showing that different groups of particles can

occur. On the one hand these are particles consisting of pure silicon or

silicon compounds (and may also contain heavy metals), on the other hand these

are particles which consist only of heavy metals. We have found primarily iron

particles, but also iron-manganese, chromium-manganese-iron and

iron-manganese-zinc containing particles.

V. DISCUSSION

Because of the production process in Tống Xá foundries, it is

obvious that dust and particles are present in the air at all production

stages. Within the foundry process, emissions to air are usually not confined

to one or more sources. In fact the production process includes several

emission sources [9]. Due to the lack of separated work areas and production

stages which are mostly situated in one production hall are housed there for

the mixing of the particles, mixing of particle emissions from different stages

is possible. Hence a defined allocation of the emissions is not possible.

Observations of the melting process showed a significant emission of melt

particles and fumes from the crucible.

According to Hasse [7] the largest part bulk of the dust emissions while

melting in induction furnaces consists of iron (45%) followed by silicon (6.5%)

and manganese (2%) (ref. Tab. 1). Particles found in our investigations

contained iron but silicon, however, had been significantly higher than Hasse

[7] described. Pure silicon particles had been detected in each sample in

different sizes and shapes. It is most probably that in these cases it concerns

quartz (SiO2) which is used in the molding shop. Caused by airflow

the fine quartz particles are raised and distributed so they are ubiquitous in

the production places.

In addition to

silica many different silicon compounds with other elements as chlorine,

calcium, potassium, sulphur, sodium and aluminium have been detected.

Particles on the

filters of the finishing process stage show, however, a significantly smaller

amount of these particles. This is related to the spatial distance of the

finishing working area related to the molding shop. In contrast to the melting

furnace which is located next to the molding shop, the finishing stage is

usually located closer to companies’ entrance. Depending on the predominant

wind direction there are not so many raised molding sand particles in this

area.

Besides chlorine,

potassium and zinc containing particles had been detected. According to Hasse [7], chlorine is used as a degasifying

agent for dissolved gases from the melt and as a flux. Zinc in the melt may

consist of alloys, such as brass or galvanized scrap parts and might evaporate

because of its lower melting point under the formation of zinc oxide smoke.

Manganese also originates from the melt for it is used as an additive and

besides it is an integral part of the crucible lining. According to Alloway [1] manganese and zinc are toxic as

dust particles.

In particles of

the melting process stage lead had also been detected using a TEM. In the

majority of the cases it has been detected in combination with Fe, Mn and Zn.

Lead is applied as a suspension for prefabricated forms and crucible lining.

Due to the high melt temperatures lead is vaporizing both in the melting

process as well as during casting. The former used anticorrosive minimum Pb3O4

for example, decomposes at 550°C to PbO which is volatile below the melting

point of 884°C [12].

In foundries

emissions from molding sands occur in addition to the ubiquitously existing

molding dusts in the finishing production stage during polishing works of the

cooled down casting products. The detected heavy metal particles of this

production stage raise also into the air by means as mechanical removal of

casting residues, surface grinding, turning or shape cutting.

In all samples

and thus throughout the air in Tống Xá foundries we detected flue ash.

These particles are approximately 1 µm to 1 mm in diameter and

originate from combustion processes and posses in addition to platelet and

fibre forms usually a smooth and solid spherical form. The composition of flue

ash is heavily dependent on the combustion raw material; usually it consists of

around 55% silica and 30% alumina as well as on but the ash can also contains

heavy metals. As the annealing furnaces of the foundries are mostly heated by

coal, heavy metals are also introduced into the air, for fossil fuels have a

natural content of heavy metals. Thus, for example lead is being emitted mainly

by burning fossil fuels.

Flue ash analyzed

in Tống Xá foundries is very rich in iron, partial manganese, chromium

and zinc. Chromium and manganese are applied in the lining material of the

crucibles and are alloys as well as surface blooming additives of the steel

scrap. Being melted they evaporate in combination with iron.

Other anthropogenic caused particles are clinker particles originating

during the casting of metals by addition of substances. Additives in the

investigated foundries are e.g. manganese, limestone and silica, which are not

soluble in the liquid metal but develop a blanket on the top of the cast

because of their lower density, the so called slag. The analyzed slag particles

consist of calcium containing aluminium silicates which often contain iron and

manganese.

In addition to these particles some fibrous magnesium-silicon compounds

have been found on the filters (ref. to Fig. 5). These silicate minerals

(asbestos compounds) are used in the crucibles lining or within building

materials in the foundries. Respirable particulate asbestos is harmful to

health [3].

Figure 5. Fibrous magnesium-silicon compounds found in

samples of the surveyed foundries in Tống Xá.

In addition to the inorganic compounds there are more pollutants from

foundries being emitted. Above all, additives in the field of organic chemistry

are applied as binding agents to the molding sand [5].

Depending on different conditions the quantity and composition of the

emissions can considerable vary. In iron foundries polycyclic aromatic

hydrocarbons (PAH) are adhering to predominately to molding sand but can also

adhere to flue dust. Volatile hydrocarbons (NMVOC) originate from binders in

the molding sand of the form and core shop (e.g. amines or resins). Emissions

of dioxins and furans can originate from evaporation and incomplete combustion

of small amounts of oil adhering to the steel scrap [2].

In addition to heavy metals and other pollutants from foundries the dust

itself poses a great problem. Especially particulate matter at high

concentrations causes an increased incidence of respiratory and cardiovascular

diseases according to WHO studies. Further studies even showed a measurable

reduction in life expectancy [2].

A standard for the characterization of fine particles is the measurand

PM10 (particulate matter <10 µm). This is understood as the fine dust

fraction with an upper particle diameter up to 10 µm. PM10 emissions occur

during all process steps: the melting process, the form and molding shop,

casting and finishing of castings [Hessisches Landesamt für Umwelt und

Geologie, 2006].

Analysis of the particle size distribution with the aerosol spectrometer

in the Việt Namese foundries showed very high concentrations of

particulate matter with particle sizes <10 µm. The maximum tolerable

concentration of 150 µg/m³ according to TCVN 5937-2005 has been exceeded

by a multiple in all investigated plants and process steps. Most notably in the

stage of casting finishing found concentrations of up to 2,500 µg/m³ has

been detected. The concentrations of particulate matter in the area of the

melting furnaces are around 500 µg/m³. According to the EU DIRECTIVE

1999/30/EC the daily limit of 50 μg/m³ for PM10 should not be

exceeded at more than 35 days per year. The tolerable annual average limit for

the protection of human health accounts for 40 µg/m³. These limits are also

exceeded by a multiple within the foundries.

In addition to the direct health related aspects within the foundries the

dust including deposited heavy metals provides severe emissions to the

surrounding environment. There are two transport ways of heavy metals to be

observed being deposited, the direct deposition close to the industrial area

and deposition via outgoing transport. Thus the problem of possible pollution

is not only concentrated locally but will be expanded to further areas with

decreasing particle concentration while distance is increasing.

VI. CONCLUSION AND

OUTLOOK

The air and particle analysis in Tống Xá showed that environmental

as well as health impacts of dust emissions within the foundries are quite

severe.

In order to reduce heavy metals and flue ash emissions in the foundries

it is necessary to implement various measures of Cleaner Production (CP).

To implement these measures, it is necessary to analyze the production

process as well as the input and the output of the surveyed foundries in

detail. These analyses are part of the Fraunhofer Institute UMSICHT within the

IWRM Vietnamese Water project.

For example one may think on a shift in the molding stage. By the use of

bentonite as a binder the dust formation can be reduced for this particular

clay is environmentally friendly, no harmful emissions are produced and

bentonite is reusable after casting up to around 94% [6].

Already emitted dusts can be removed from air by filtering processes,

e.g. electro filter.

A far more simple and fast action to be implemented would be the

introduction of improved occupational safety and health conditions. For example

by the compulsory wearing of dust masks foundry workers health could be

strongly enhanced.

Acknowledgments: The

German Federal Ministry of Education and Research is funding the research work

published in here within the framework of the IWRM Việt Nam Water project

under the Reference No. FKZ 02 WM 0765 and 02 WM 0767. All

work in Tống Xá village was kindly supported by the Peoples Committee of

Yen Xa commune and Nam Dinh Provincial Department of Science and Technology

(DoST). We would like to thank GRIMM Aerosol Technik GmbH & Co. KG in Ainring for their support. Besides the

authors would like to thank Ms. Jasmin Pervaz who supported the project during

her practical training with great effort.

REFERENCES

1. Alloway Brian J., 1995. Heavy metals in

soils: Analytics,

concentrations, interactions.

2. Austrian Federal

Environment Agency, 2006. PRTR - Europäisches

Schadstofffreisetzungs- und –verbringungsregister.

3. Bliefert K., 2002. Environmental

chemistry. Third revised edition. Weinheim,

VCH.

4. Emmerich, R., 2007. Foundries in Tống

Xá - Field survey. Internal report.

5.

Freiburger Institute for Environmental Chemistry, 2007. Bericht zur vorläufigen Einschätzung der Emissionen

der Gießerei Karcher. [http://www.edith-sitzmann.de/fileadmin/user_upload/dateien/Politik_fuer_Freiburg/Gutachten_Sturmer.pdf]

6. Grefhorst

C., 2006. Prüfung

von Bentoniten - Ausführliche Bewertung der Eigenschaften und

ihr Wert für die Praxis. In: Gießerei [http://www.ikominerals.com/fileadmin/pdf/sb_giesserei

/Fachbeitraege/G_0506_S26-31.pdf].

7. Hasse S., 2001. Gießereilexikon. Schiele &

Schön.

8. Keuter V., 2009. CP measures in

Vietnamese foundries - Results, recommendations and outlook, presentation. IWRM-Workshop

9. Lahmann E., Munari S., Amicarelli V., 1987. Heavy metals: Identification of air quality and environmental

problems in the European Community. Vol.

1.

10. Lê Thị Lài, Nguyễn Thị Hằng,

2003. General characterization of

the craft-settlements Vân Chàng, Xuân Tiến and Tống Xá in

11. EU Directive 1999/30/EG des Rates der

Europäischen Union vom 22, 1999 über Grenzwerte für Schwefeldioxid,

Stickstoffdioxid, Stickstoffoxide, Partikel und Blei in der Luft.

12. Riedel Erwin unter Mitw. von J. Christoph, 2002. Anorganische Chemie. Berlin; New

York: de Gruyter.

13. Umweltbundesamt für Mensch und

Umwelt, 2004. Integrierte Vermeidung und Verminderung der

Umweltverschmutzung (IVU). Referenzdokument

über die Besten Verfügbaren Techniken für Schmieden und Gießereien.